China wholesale Compressed Air Dryer - High Pressure Air Dryer Refrigerated Type 30bar Compressed Air Dryer for Compressor Tr-80 – Tianer

China wholesale Compressed Air Dryer - High Pressure Air Dryer Refrigerated Type 30bar Compressed Air Dryer for Compressor Tr-80 – Tianer Detail:

Parameter

| TR series refrigerated air dryer | TR-80 | ||||

| Max air volume | 3000CFM | ||||

| Power supply | 380V / 50HZ (Other power can be customized) | ||||

| Input power | 16.1HP | ||||

| Air pipe connection | DN125 | ||||

| Evaporator type | Aluminum alloy plate | ||||

| Refrigerant model | R407C | ||||

| System max pressure drop | 3.625 PSI | ||||

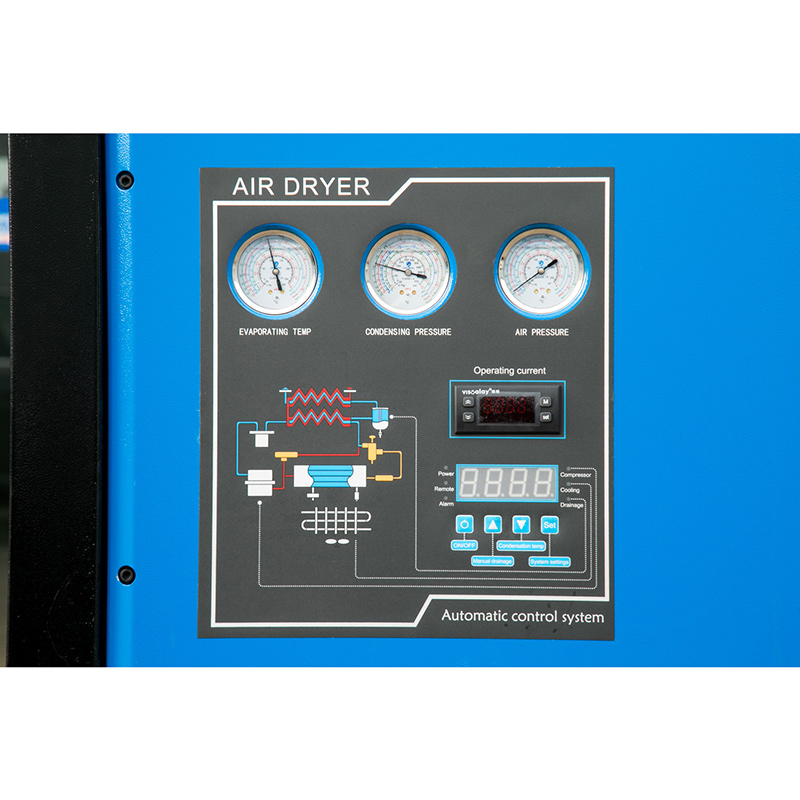

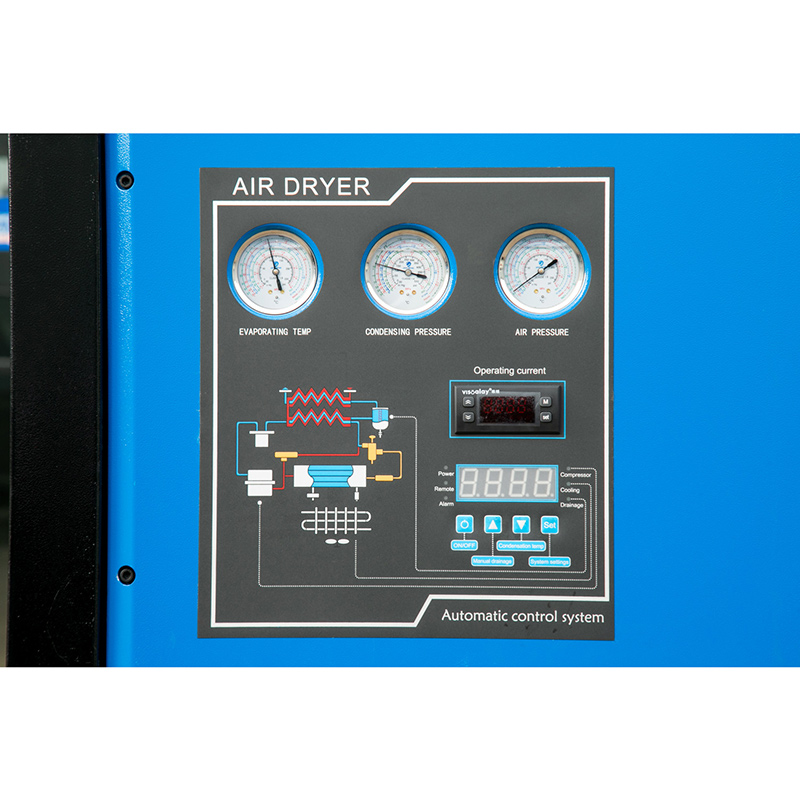

| Display interface | LED dew point display, LED alarm code display,operation status indication | ||||

| Intelligent anti-freezing protection | Constant pressure expansion valve and compressor automatic start/stop | ||||

| Temperature control | Automatic control of condensing temperature/dew point temperature | ||||

| High voltage protection | Temperature sensor | ||||

| Low voltage protection | Temperature sensor and inductive intelligent protection | ||||

| Weight(kg) | 920 | ||||

| Dimensions L × W × H(mm) | 1850*1350*1850 | ||||

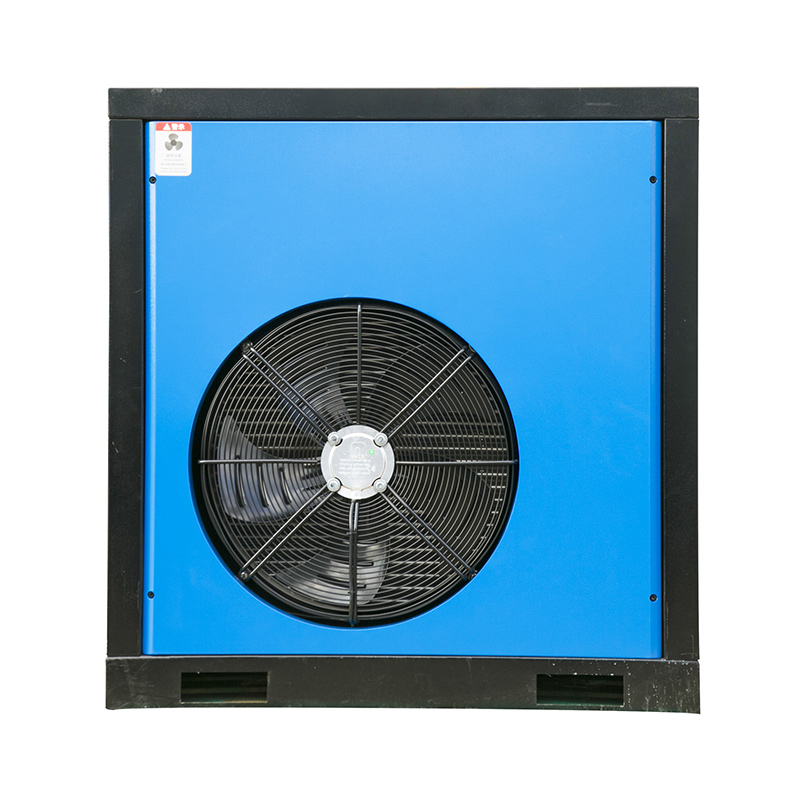

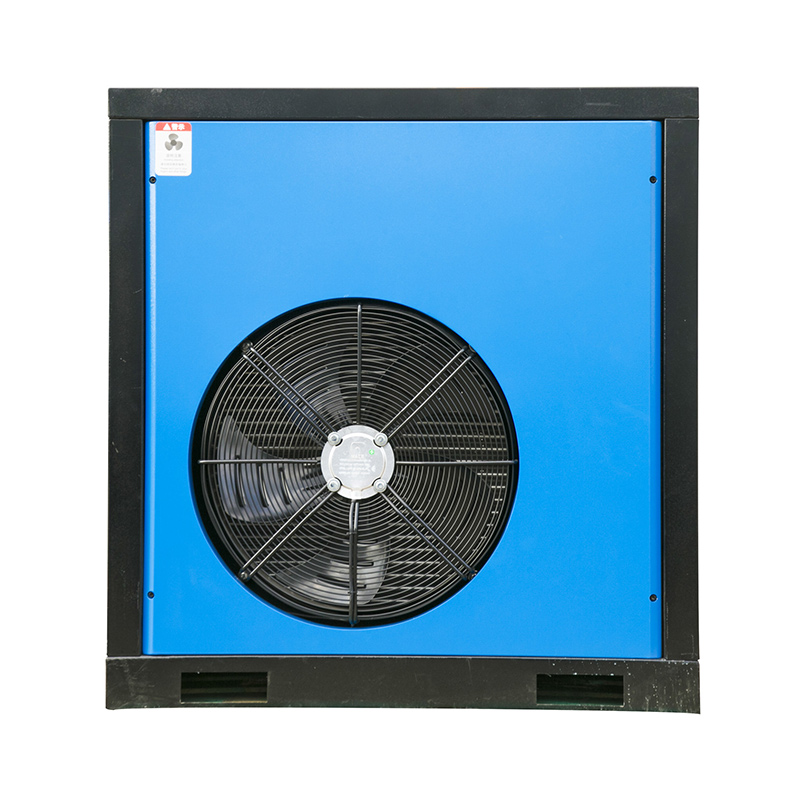

| Installation environment: | No sun, no rain, good ventilation, device level hard ground, no dust and fluff | ||||

TR Series Condition

| 1. Ambient temperature: 38℃, Max. 42℃ | |||||

| 2. Inlet temperature: 38℃, Max. 65℃ | |||||

| 3. Working pressure: 0.7MPa, Max.1.6Mpa | |||||

| 4. Pressure dew point: 2℃~10℃(Air dew point:-23℃~-17℃) | |||||

| 5. No sun, no rain, good ventilation, device level hard ground, no dust and fluff |

TR Series Refrigerated Air Dryer

| TR series refrigerated Air dryer |

Model | TR-15 | TR-20 | TR-25 | TR-30 | TR-40 | TR-50 | TR-60 | TR-80 | |

| Max. air volume | m3/min | 17 | 23 | 28 | 33 | 42 | 55 | 65 | 85 | |

| Power supply | 380V/50Hz | |||||||||

| Input power | KW | 3.7 | 4.9 | 5.8 | 6.1 | 8 | 9.2 | 10.1 | 12 | |

| Air pipe connection | RC2″ | RC2-1/2″ | DN80 | DN100 | DN125 | |||||

| Evaporator type | Aluminum alloy plate | |||||||||

| Refrigerant model | R407C | |||||||||

| System Max. pressure drop |

0.025 | |||||||||

| Intelligent control and protection | ||||||||||

| Display interface | LED dew point display, LED alarm code display,operation status indication | |||||||||

| Intelligent anti-freezing protection | Constant pressure expansion valve and compressor automatic start/stop | |||||||||

| Temperature control | Automatic control of condensing temperature/dew point temperature | |||||||||

| High voltage protection | Temperature sensor | |||||||||

| Low voltage protection | Temperature sensor and inductive intelligent protection | |||||||||

| Energy saving: | KG | 180 | 210 | 350 | 420 | 550 | 680 | 780 | 920 | |

| Dimension | L | 1000 | 1100 | 1215 | 1425 | 1575 | 1600 | 1650 | 1850 | |

| W | 850 | 900 | 950 | 1000 | 1100 | 1200 | 1200 | 1350 | ||

| H | 1100 | 1160 | 1230 | 1480 | 1640 | 1700 | 1700 | 1850 | ||

Lowering the temperature of the compressed air reduces the amount of water vapor in the compressed air while keeping the pressure of the compressed air essentially constant, and the excess water vapor condenses into liquid. Cold drying machine is the use of this principle using refrigeration technology dry compressed air.

It consists of four basic components: refrigeration compressor, condenser, evaporator and expansion valve. They are connected in turn by pipes to form a closed system in which the refrigerant is constantly circulating, changing state and exchanging heat with compressed air and cooling media

The refrigeration compressor draws the low pressure (low temperature) refrigerant in the evaporator into the compressor. The refrigerant steam is compressed, and the pressure and temperature rise at the same time. The refrigerant steam with high pressure and high temperature is pressed to the condenser. In the condenser, the refrigerant steam with higher temperature is heat exchanged with cooling water or air with lower temperature. The refrigerant heat is taken away by water or air and condensed, and the refrigerant steam becomes liquid. This part of the liquid is then transported to the expansion valve, through the expansion valve throttled into low temperature and low pressure liquid and into the evaporator; In the evaporator, the low temperature and low pressure refrigerant liquid absorbs the heat of compressed air and vaporizes (commonly known as “evaporation”), while the compressed air condenses a large amount of liquid water after cooling; The refrigerant steam in the evaporator is sucked away by the compressor, so that the refrigerant in the system through compression, condensation, throttling, evaporation, so as to complete a cycle.

In the refrigeration system of cold drying machine, the evaporator is the equipment for conveying cold quantity, in which the refrigerant absorbs the heat of compressed air to achieve the purpose of dehydration and drying. Compressor is the heart, plays the role of suction, compression, transport refrigerant steam. Condenser is a device that emits heat, transferring the heat absorbed in the evaporator together with the heat converted from the input power of the compressor to the cooling medium (such as water or air) away. The expansion valve/throttle valve throttles and depresses the refrigerant, controls and regulates the flow of refrigerant liquid into the evaporator, and divides the system into two parts: high pressure side and low pressure side. In addition to the above components, the cold and dry machine also includes energy regulating valve, high and low pressure protector, automatic blowdown valve, control system and other components.

Energy saving:

The aluminum alloy three-in-one heat exchanger design minimizes the process loss of the cooling capacity and improves the recycling of the cooling capacity. Under the same processing capacity, the total input power of this model is reduced by 15-50%

High Efficiency:

The integrated heat exchanger is equipped with guide fins to make the compressed air evenly exchange heat inside, and the built-in steam-water separation device is equipped with a stainless steel filter to make the water separation will be more thoroughly.

Intelligent:

Multi-channel temperature and pressure monitoring, real-time display of dew point temperature, automatic recording of accumulated running time, self-diagnosis function, display of corresponding alarm codes, and automatic protection of equipment

Environmental protection:

In response to the International Montreal Agreement, this series of models all use R134a and R410a environmentally friendly refrigerants, which will cause zero damage to the atmosphere and meet the needs of the international market.

Compact structure and small size

The plate heat exchanger has a square structure and occupies a small space. It can be flexibly combined with refrigeration components in the equipment without excessive space waste.

Product Display

Product detail pictures:

Related Product Guide:

abide by the contract", conforms into the market requirement, joins in the market competition by its good quality also as provides a lot more comprehensive and great company for purchasers to let them turn into huge winner. The pursue from the firm, would be the clients' gratification for China wholesale Compressed Air Dryer - High Pressure Air Dryer Refrigerated Type 30bar Compressed Air Dryer for Compressor Tr-80 – Tianer , The product will supply to all over the world, such as: Algeria, Bandung, Estonia, We will supply much better products with diversified designs and professional services. At the same time, welcome OEM, ODM orders, invite friends at home and abroad together common development and achieve win-win, integrity innovation, and expand business opportunities! If you have any question or need more information please feel free to contact us. We are looking forward to receiving your enquiries soon.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!