Generally, the double-tower adsorption air dryer needs a major maintenance every two years. Next, let’s learn about the operation process of replacing the adsorbent. Activated alumina is usually used as the adsorbent. Molecular sieves can be used for higher requirements.

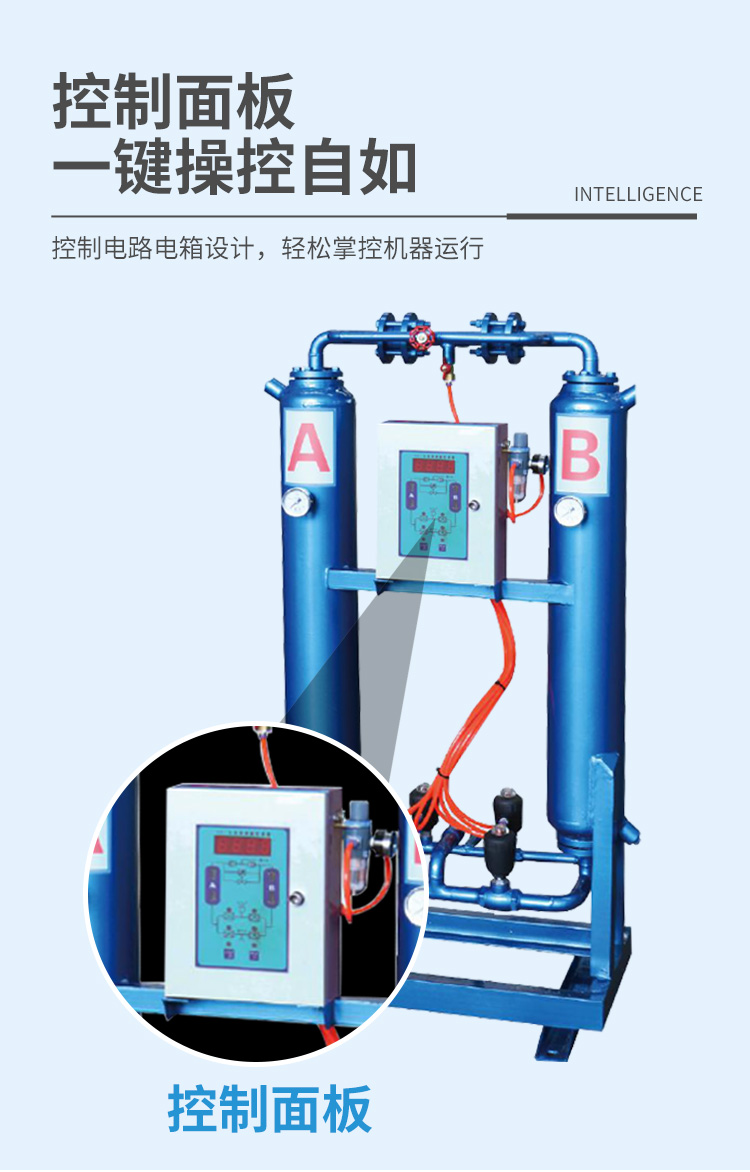

We will use a basic heatless regenerative double-tower adsorption air dryer as an illustration:

First find the discharge port, as shown in Figure 1. Adsorbent needs to be drained clean.

Then open the muffler, as shown in Figure 2, check whether there is any adsorbent residue in the pipeline, if there are particles, it is necessary to replace the diffuser at the bottom of the dryer barrel. Finally close the discharge port.

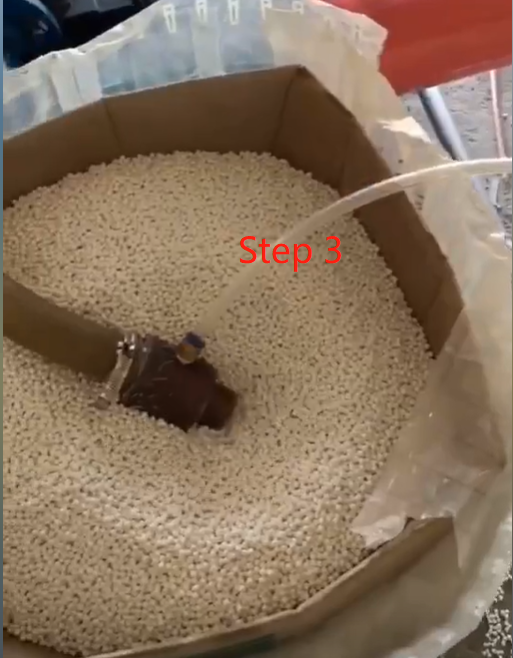

Open the upper feeding port and fill the adsorbent tank to the top. Special attention should be paid here that it must be filled to the feeding port so that the adsorbent can be seen, and the whole maintenance process is completed.

Post time: May-25-2023