OEM Factory for Heatless Adsorption Dryer - Refrigerated Air Dryer Manufacturer Air Compressor Dryer Freeze Drying Equipment – Tianer

OEM Factory for Heatless Adsorption Dryer - Refrigerated Air Dryer Manufacturer Air Compressor Dryer Freeze Drying Equipment – Tianer Detail:

Parameter

| TR series refrigerated air dryer | TR-15 | ||||

| Max air volume | 600CFM | ||||

| Power supply | 380V / 50HZ (Other power can be customized) | ||||

| Input power | 5HP | ||||

| Air pipe connection | RC2” | ||||

| Evaporator type | Aluminum alloy plate | ||||

| Refrigerant model | R407C | ||||

| System max pressure drop | 3.625 PSI | ||||

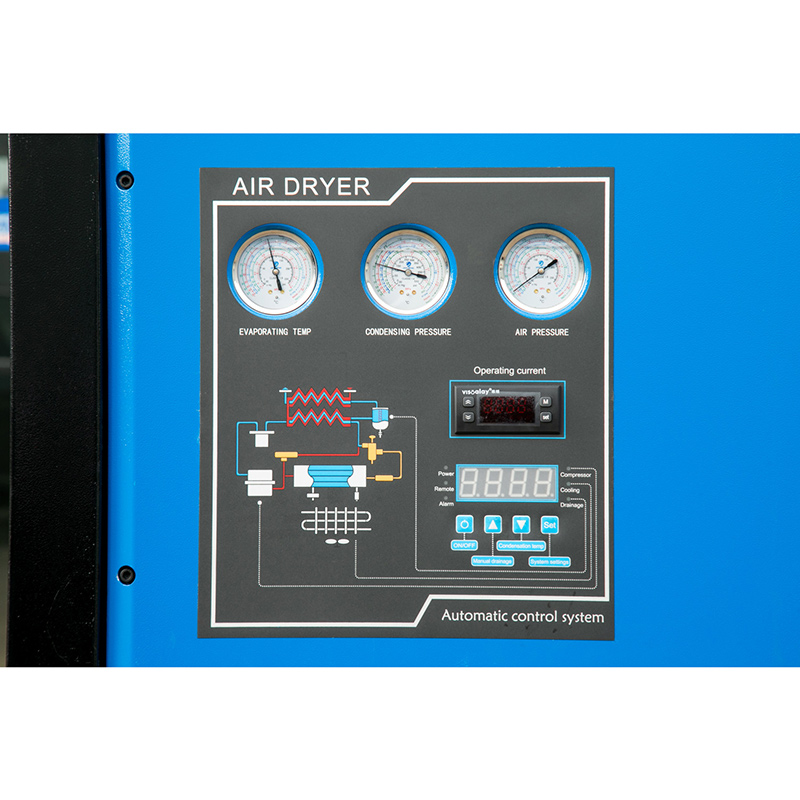

| Display interface | LED dew point display, LED alarm code display,operation status indication | ||||

| Intelligent anti-freezing protection | Constant pressure expansion valve and compressor automatic start/stop | ||||

| Temperature control | Automatic control of condensing temperature/dew point temperature | ||||

| High voltage protection | Temperature sensor | ||||

| Low voltage protection | Temperature sensor and inductive intelligent protection | ||||

| Weight(kg) | 180 | ||||

| Dimensions L × W × H(mm) | 1000*850*1100 | ||||

| Installation environment: | No sun, no rain, good ventilation, device level hard ground, no dust and fluff | ||||

TR Series Condition

| 1. Ambient temperature: 38℃, Max. 42℃ | |||||

| 2. Inlet temperature: 38℃, Max. 65℃ | |||||

| 3. Working pressure: 0.7MPa, Max.1.6Mpa | |||||

| 4. Pressure dew point: 2℃~10℃(Air dew point:-23℃~-17℃) | |||||

| 5. No sun, no rain, good ventilation, device level hard ground, no dust and fluff |

TR Series Refrigerated Air Dryer

| TR series refrigerated Air dryer |

Model | TR-15 | TR-20 | TR-25 | TR-30 | TR-40 | TR-50 | TR-60 | TR-80 | |

| Max. air volume | m3/min | 17 | 23 | 28 | 33 | 42 | 55 | 65 | 85 | |

| Power supply | 380V/50Hz | |||||||||

| Input power | KW | 3.7 | 4.9 | 5.8 | 6.1 | 8 | 9.2 | 10.1 | 12 | |

| Air pipe connection | RC2″ | RC2-1/2″ | DN80 | DN100 | DN125 | |||||

| Evaporator type | Aluminum alloy plate | |||||||||

| Refrigerant model | R407C | |||||||||

| System Max. pressure drop |

0.025 | |||||||||

| Intelligent control and protection | ||||||||||

| Display interface | LED dew point display, LED alarm code display,operation status indication | |||||||||

| Intelligent anti-freezing protection | Constant pressure expansion valve and compressor automatic start/stop | |||||||||

| Temperature control | Automatic control of condensing temperature/dew point temperature | |||||||||

| High voltage protection | Temperature sensor | |||||||||

| Low voltage protection | Temperature sensor and inductive intelligent protection | |||||||||

| Energy saving: | KG | 180 | 210 | 350 | 420 | 550 | 680 | 780 | 920 | |

| Dimension | L | 1000 | 1100 | 1215 | 1425 | 1575 | 1600 | 1650 | 1850 | |

| W | 850 | 900 | 950 | 1000 | 1100 | 1200 | 1200 | 1350 | ||

| H | 1100 | 1160 | 1230 | 1480 | 1640 | 1700 | 1700 | 1850 | ||

Cold dryer configuration:

Generally speaking, the cold dryer should not be directly connected to the exhaust of the air compressor. Air compressor exhaust must first pass through a series of post-processing equipment and necessary filters before entering the dryer.

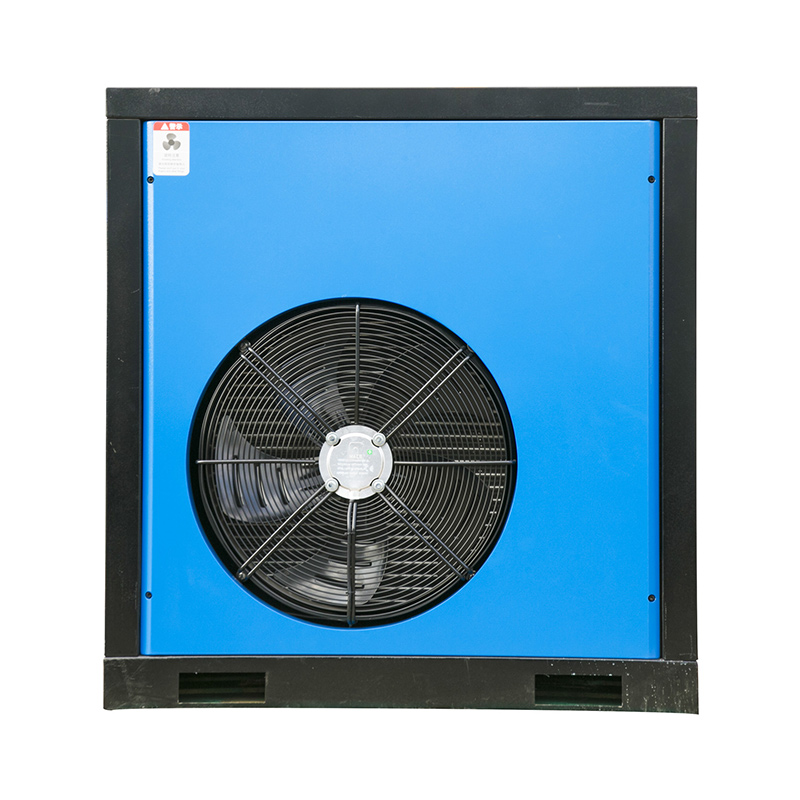

The use environment of the cold dryer:

The cold dryer has certain requirements for the environment. High ambient temperature is very detrimental to the heat dissipation of the refrigeration system of the refrigerating machine. When the ambient temperature is higher than the condensing temperature required by the normal working conditions of the refrigerant, the condensing pressure is forced to increase, the cooling capacity will decrease, and the power consumption of the compressor will increase significantly, resulting in The economic and technical indicators of the refrigeration dryer are comprehensively deteriorated. Therefore, it is required that the environment of the air-cooled dryer should not only be lower than the specified value, but also must be well ventilated so that the working heat does not accumulate around the machine; the inlet water temperature of the water-cooled dryer must be controlled below the specified temperature. The use of refrigerated dryers in excess of the rated ambient temperature will inevitably entail corresponding economic or quality costs. Generally speaking, a lower ambient temperature is conducive to the operation of the dryer. When using a cold dryer at a too low ambient temperature (for example, below zero), because there is not much moisture in the air, the accumulated water in the automatic drain can be drained at a long interval, so it is necessary to prevent the accumulation of water in the cup. The water freezes and damages the device. In fact, many refrigerated dryers are not allowed to be used in an environment of 2 °C.

In addition, the refrigerating machine should be installed far away from the air compressor, so as to avoid the influence of the heat released by the air compressor.

Energy saving:

The aluminum alloy three-in-one heat exchanger design minimizes the process loss of the cooling capacity and improves the recycling of the cooling capacity. Under the same processing capacity, the total input power of this model is reduced by 15-50%

High Efficiency:

The integrated heat exchanger is equipped with guide fins to make the compressed air evenly exchange heat inside, and the built-in steam-water separation device is equipped with a stainless steel filter to make the water separation will be more thoroughly.

Intelligent:

Multi-channel temperature and pressure monitoring, real-time display of dew point temperature, automatic recording of accumulated running time, self-diagnosis function, display of corresponding alarm codes, and automatic protection of equipment

Environmental protection:

In response to the International Montreal Agreement, this series of models all use R134a and R410a environmentally friendly refrigerants, which will cause zero damage to the atmosphere and meet the needs of the international market.

High heat exchange efficiency

The flow channel of the plate heat exchanger is small, the plate fins are waveforms, and the cross-section changes are complicated. A small plate can obtain a larger heat exchange area, and the flow direction and flow rate of the fluid are constantly changed, which increases the flow rate of the fluid. Disturbance, so it can reach turbulent flow at a very small flow rate. In the shell-and-tube heat exchanger, the two fluids flow in the tube side and the shell side respectively. Generally, the flow is cross-flow, and the logarithmic average temperature difference correction coefficient is small. ,

Photos (Color can be customized)

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for OEM Factory for Heatless Adsorption Dryer - Refrigerated Air Dryer Manufacturer Air Compressor Dryer Freeze Drying Equipment – Tianer , The product will supply to all over the world, such as: Latvia, Bangkok, Malaysia, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.